Cobot welding

Precision robotic welding for small series and single components

Your solutions for next-gen cobot welding cells

In today’s manufacturing industry, collaborative robots, or cobots, have become indispensable partners in the field of welding technology. These welding robots are revolutionizing automated welding by putting efficiency, precision, and safety front and center. Whether you’re working with small, complex components or large, cumbersome structures—we offer the right cobot solution for every application.

Our innovative cobot systems are designed to adapt flexibly to your specific requirements in production. Optimized for a variety of applications, our range of three different cobots has a solution for everything from fine machining small parts through to robust handling for large components. They are versatile and adaptable to meet the highest standards in welding technology. Discover the future of welding—with our tailor-made solutions for your manufacturing.

The advantages for you

Low total cost of ownership

The cobot welding cells from Fronius are cost-efficient and soon pay for themselves, a key advantage for small and mid-sized companies in particular.

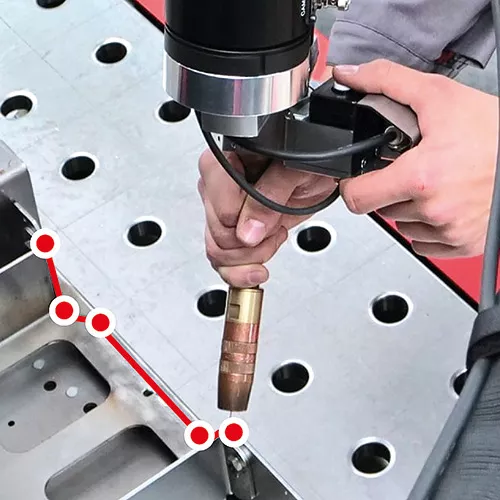

Simple, user-friendly operation

You don’t need any special programming skills to operate the Fronius cobot welding cells. The user interface is intuitive and speeds up the training process.

High flexibility

The welding cells are suitable for various component geometries and are easy to adjust to different production requirements.

Consistent, reproducible welding quality

Thanks to precise welding torch movements and intelligent welding technology, the cobot welding cells deliver a consistently high standard of quality, regardless of batch size.

Increased safety

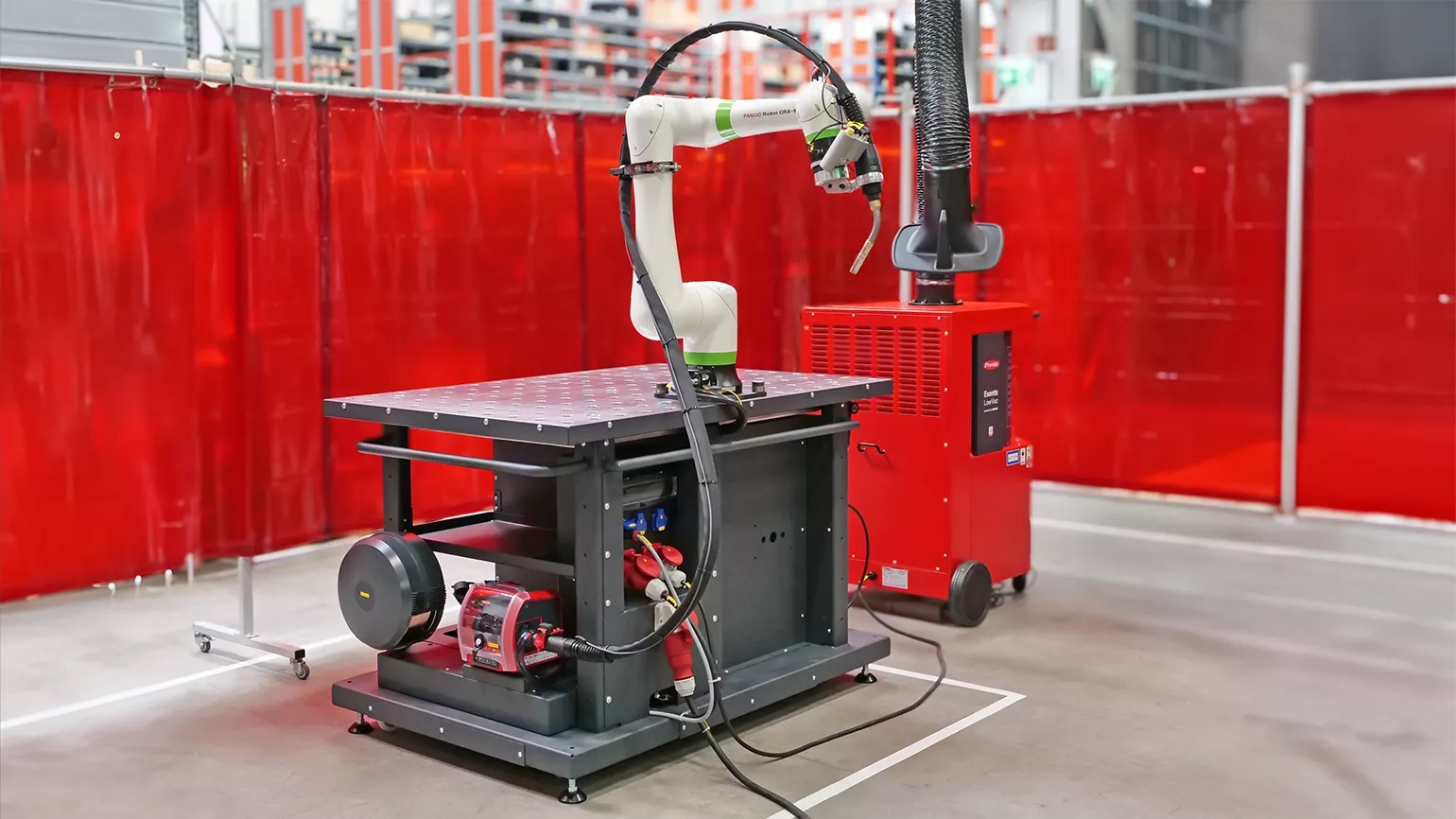

The welding cells are fitted with CE-compliant safety devices to guarantee a safe working environment.Portable cobot welding—CWC-mobile

The Fronius CWC-mobile provides for portability in cobot welding. Its compact design, including the transport unit with casters and retractable feet, makes it easy to move the welding cell between different large components. CWC-mobile fulfills statutory safety requirements, is CE-certified, and has a portable glare shield (EN ISO 25980) in the form of safety curtains. Not only that, the welding table makes it simple to weld small series.

Highlights:

- Portable and flexible

- CE-certified safety concept

- Designed for collaboration

System overview

CE safety package

The CWC-mobile cobot solution comes complete with a CE-compliant safety package to guarantee protection for employees’ health and safety.

This package includes:

- Power and torque limiter for the cobot

- Fume extraction unit

- Portable glare shield

- Personal protective equipment

- Puncture-proof gloves

- Protective clothing

- Welding helmet

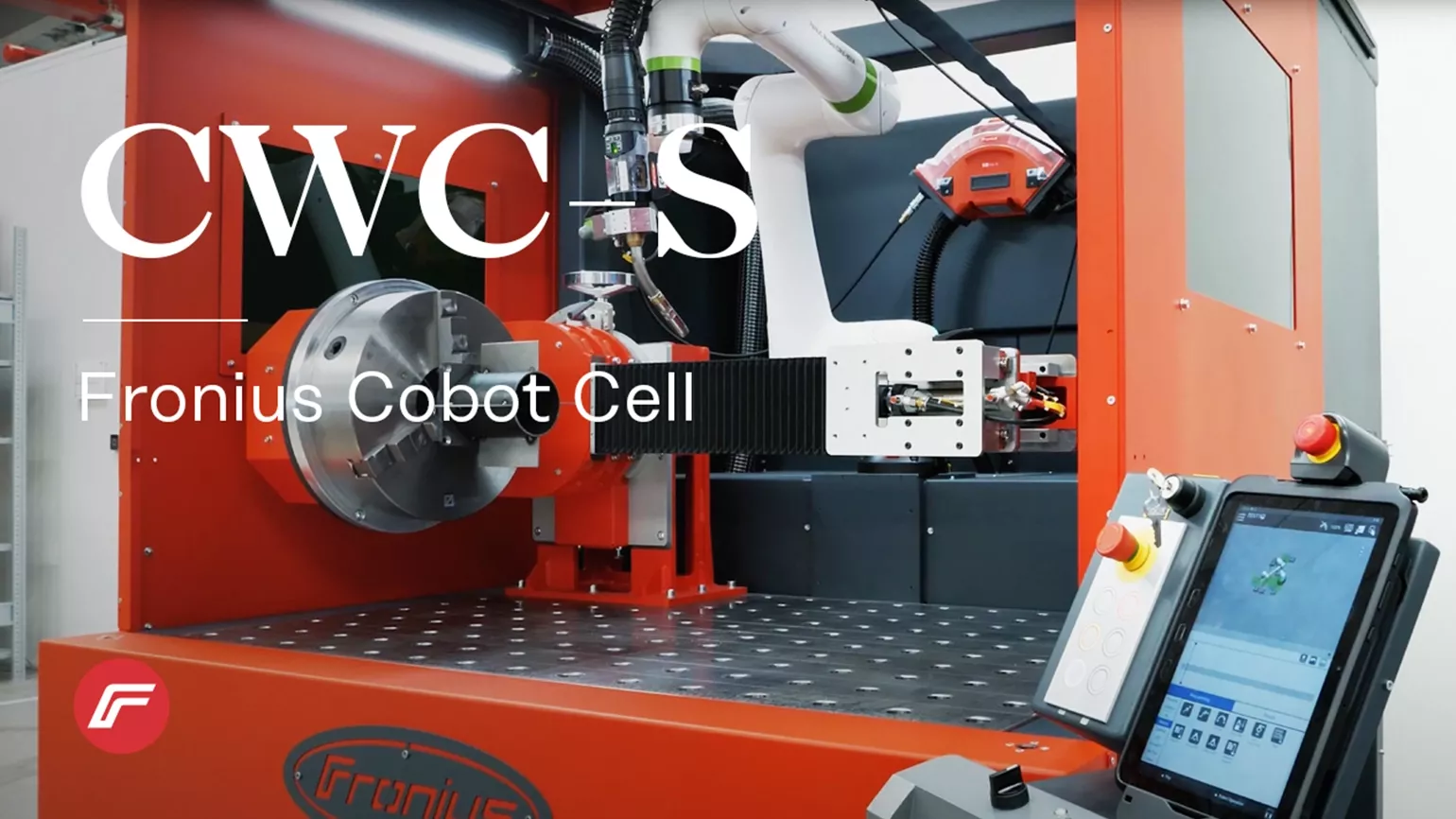

Profitable even with small batch sizes—CWC-S

The CWC-S cobot welding cell is the easy, cost-effective way to get started with automated welding. This welding cell combines the latest robot technology with the proven welding expertise you’ve come to expect from Fronius. Developed for use in small to mid-sized series production, the CWC-S offers user-friendliness and the highest safety standards. A compact design and easy programming make this the ideal solution for companies looking to optimize their welding processes while tackling the challenges of the skills shortage.

Highlights:

- Low total cost of ownership

- Cost-effective even for small batch sizes

- Simple, user-friendly operation—no programming skills required

- CE-compliant safety housing

System overview

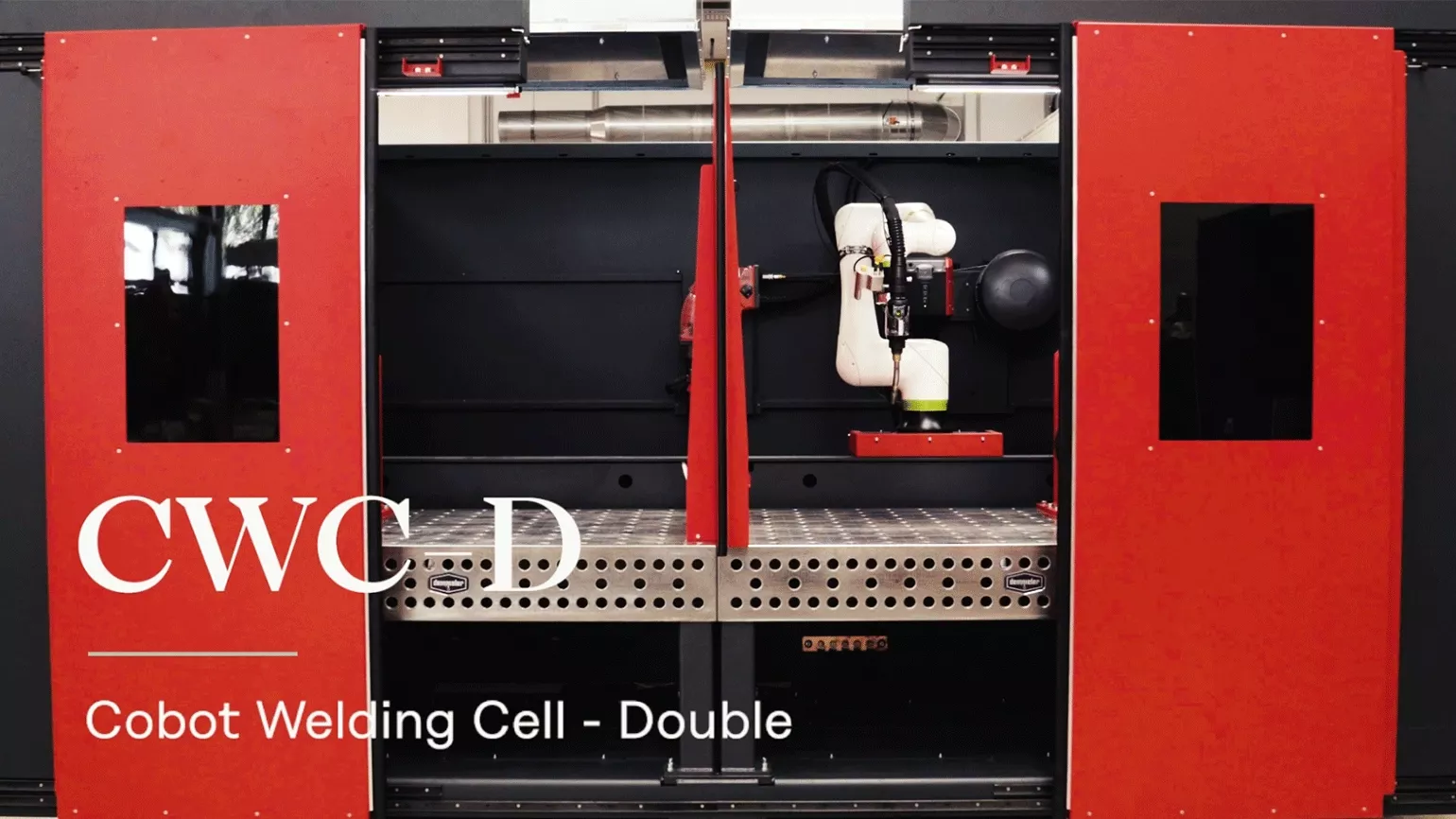

Cobot welding made flexible, productive, and profitable—CWC-D

The Fronius CWC-D cobot welding cell is all about cost effective welding—from small batch runs through to series production. The welding cell provides for maximum flexibility: one-station operation for large workpieces, or two-station operation to set up and weld in parallel. Programming is made easy using drag and drop, with no prior knowledge of robot programming required.

Highlights:

- Two stations for high productivity

- High flexibility thanks to expanded working area

- The entire cobot cell comes CE certified as standard

System overview

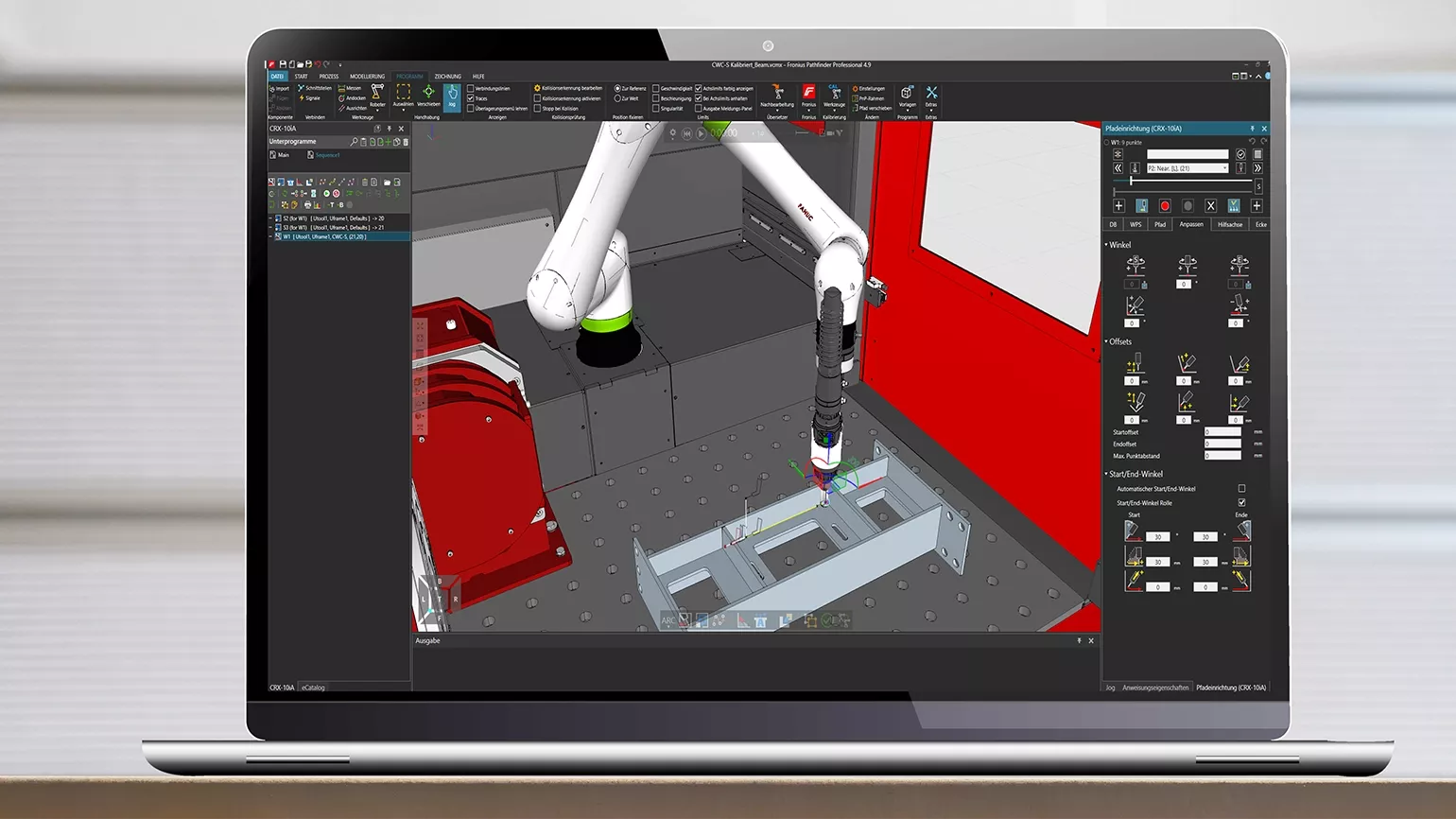

Boost productivity with Fronius Pathfinder

When using cobot welding cells, offline programming offers the advantage of creating and testing programs without having to stop ongoing production. This minimizes downtimes while boosting productivity. Finished programs can simply be transferred to the welding cell and adjusted directly on the cobot if needed.

- Production continues uninterrupted thanks to offline programming

- Up to 80% time savings when programming complex component geometries

- Perfect integration with hardware and software from a single source