ALTEC Aluminium-Technik GmbH & Co. KGaA

Access solutions made easy

From rolling scaffolds, facade scaffolds, and flat roof fall protection systems to complete docking systems for aviation and numerous special solutions: ALTEC Aluminium-Technik GmbH & Co. KGaA, based in the German town of Mayen, in Rhineland-Palatinate, builds all forms of access solution. In doing so, 95 percent of the company’s business is in lightweight aluminum construction. Thanks to its 35 years of experience in welding aluminum components, the specialist welding company certified to EN 1090-1 and 1090-3 is able to realize even the most complex orders.

ALTEC Aluminium-Technik GmbH & Co. KGaA

Headquarters:

Mayen, Germany

Founded:

1985

Employees:

< 50

Production of:

Aluminum products

Scaffolds

Fall protection systems

Docking systems

Fronius products in use:

TPS 320i

Process application:

CMT

PMC Ripple Drive

The modernization of the system has reduced downtimes to such an extent that they hardly ever occur. The high process stability of the Fronius welding system has therefore thoroughly impressed us.

Challenge

Despite, or perhaps thanks to, the company’s compact size with 50 employees, ALTEC relies on forward-looking production methods: “This includes state-of-the-art CAD workstations, as well as fully automated robotic welding cells and the associated high-tech welding process technology,” explains ALTEC plant manager Siegfried Berenz, a trained master metalworker and international welding specialist (IWS).

As part of the process of advancing automation, in 2018 an aluminum framework part (AlSi1, two millimeters) was to be transferred from manual production to robotic welding. The focus here was on high welding speed in conjunction with maximum process reliability.

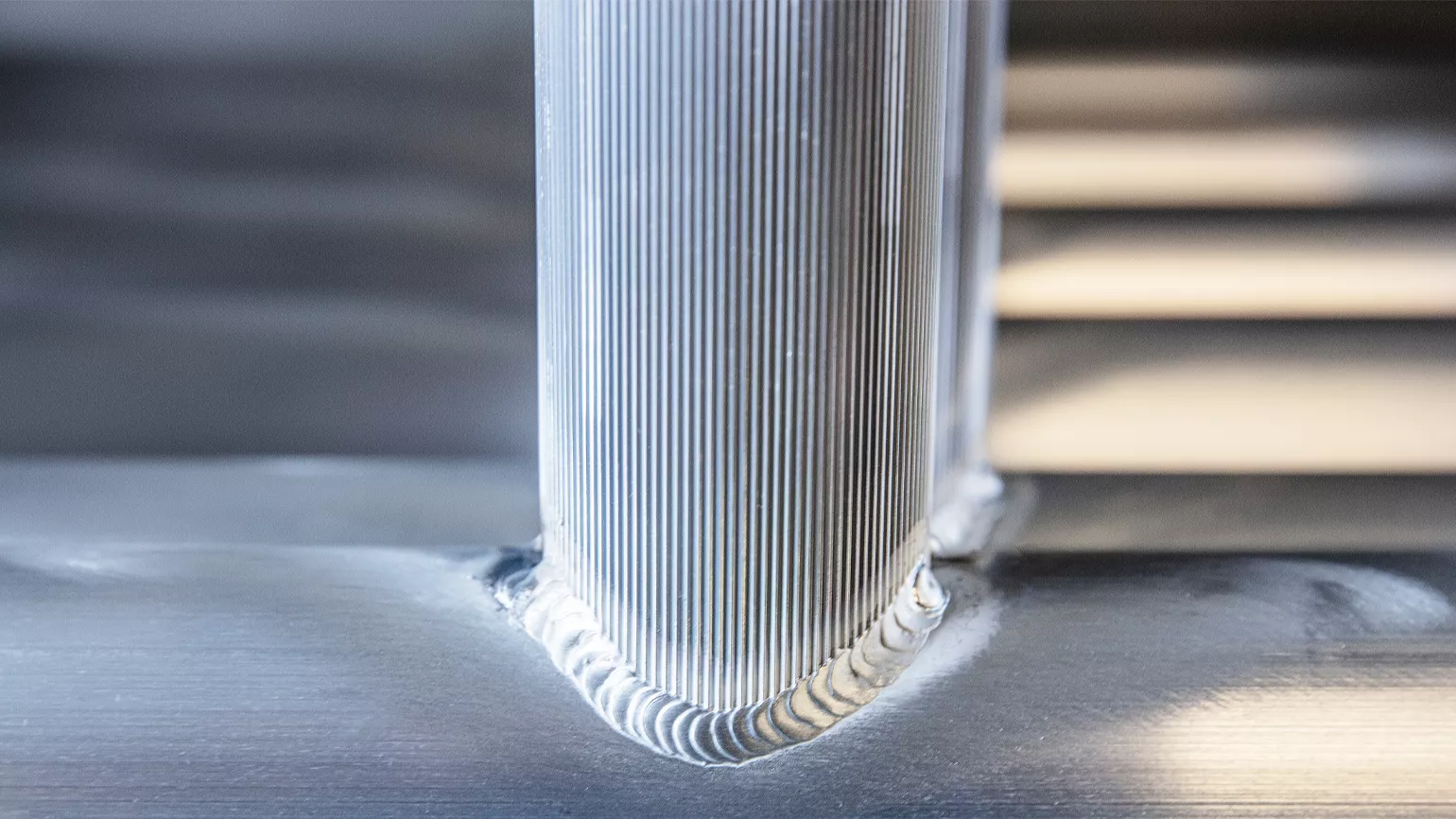

A short time later, it was necessary to equip a further existing robot system with new welding technology due to high failure rates. In this case, the unmanipulated welding runs through the vertical-up seam, flat position, and vertical down seam in a single step. One process for all position welds without moving the workpiece was thus a basic requirement. The weld seam appearance also had to be outstanding.

Solution

The Fronius TPS 320i high-tech welding system platform is used on both robotic welding systems. Both power sources are also equipped with the complete CMT hardware. ALTEC also found the ideal solution for the challenge of 2018 in the Fronius CMT welding process. This is because the process can deliver high welding speeds and outstanding process reliability, particularly on light-gage metal sheet. As a result, Fronius was able to establish itself in ALTEC’s production.

During the subsequent retrofit of the existing robot system, the decision was made in favor of the Fronius PMC Ripple Drive pulse welding process variant. The perfect weld properties in out-of-position welding and the large gap-bridging ability, as well as the high degree of process reliability and the TIG-like weld seam appearance were particularly impressive. As a result, failures and component scrap dropped to around zero.