WeldCube Air

Die Zukunft des digitalen Datenmanagements

Grenzenloser Überblick

WeldCube Air ist eine sichere, cloudbasierte Plattform zur einfachen Verbindung und Visualisierung von Schweißdaten. Die Anwendung erfordert keine aufwendige Installation, ist sofort einsatzbereit und ermöglicht die effiziente Verwaltung Ihrer schweißtechnischen Fertigung. Jederzeit und überall – ob am PC, im Büro oder von unterwegs mit Ihrem mobilen Gerät.

Mit WeldCube Air haben Sie Zugriff auf:

- Schweißgerätemanagement

- Produktivitätsanalyse

- WPS & Qualifikationen

Digital verwaltet, optimal genutzt

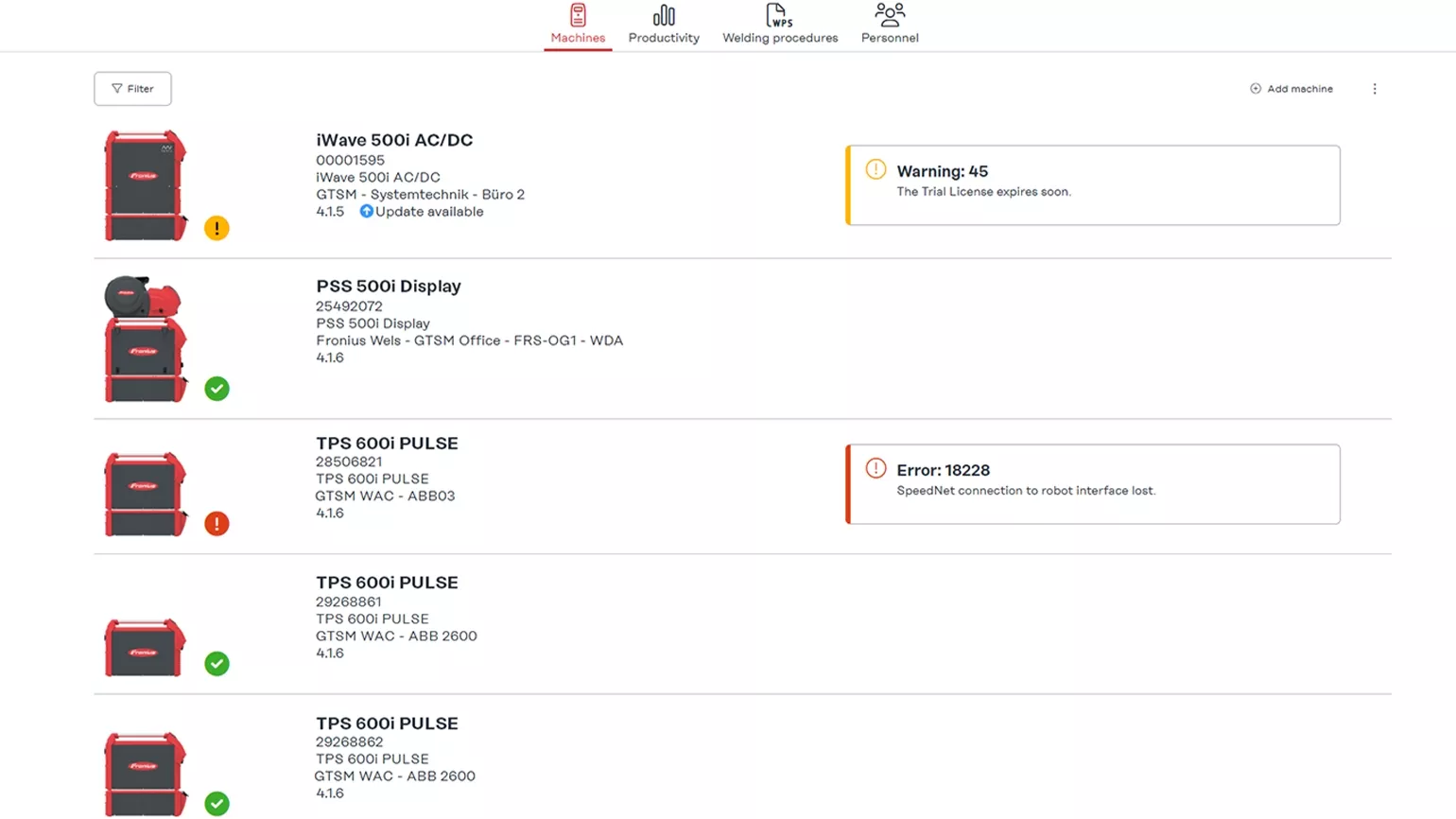

WeldCube Air macht Ihr Schweißgerätemanagement intuitiv und effizient. Die digitale Verwaltung der Schweißgeräte spart nicht nur Zeit, sondern sorgt für eine übersichtliche Organisation der Systemdaten. So bleibt Ihre Flotte jederzeit einsatzbereit.

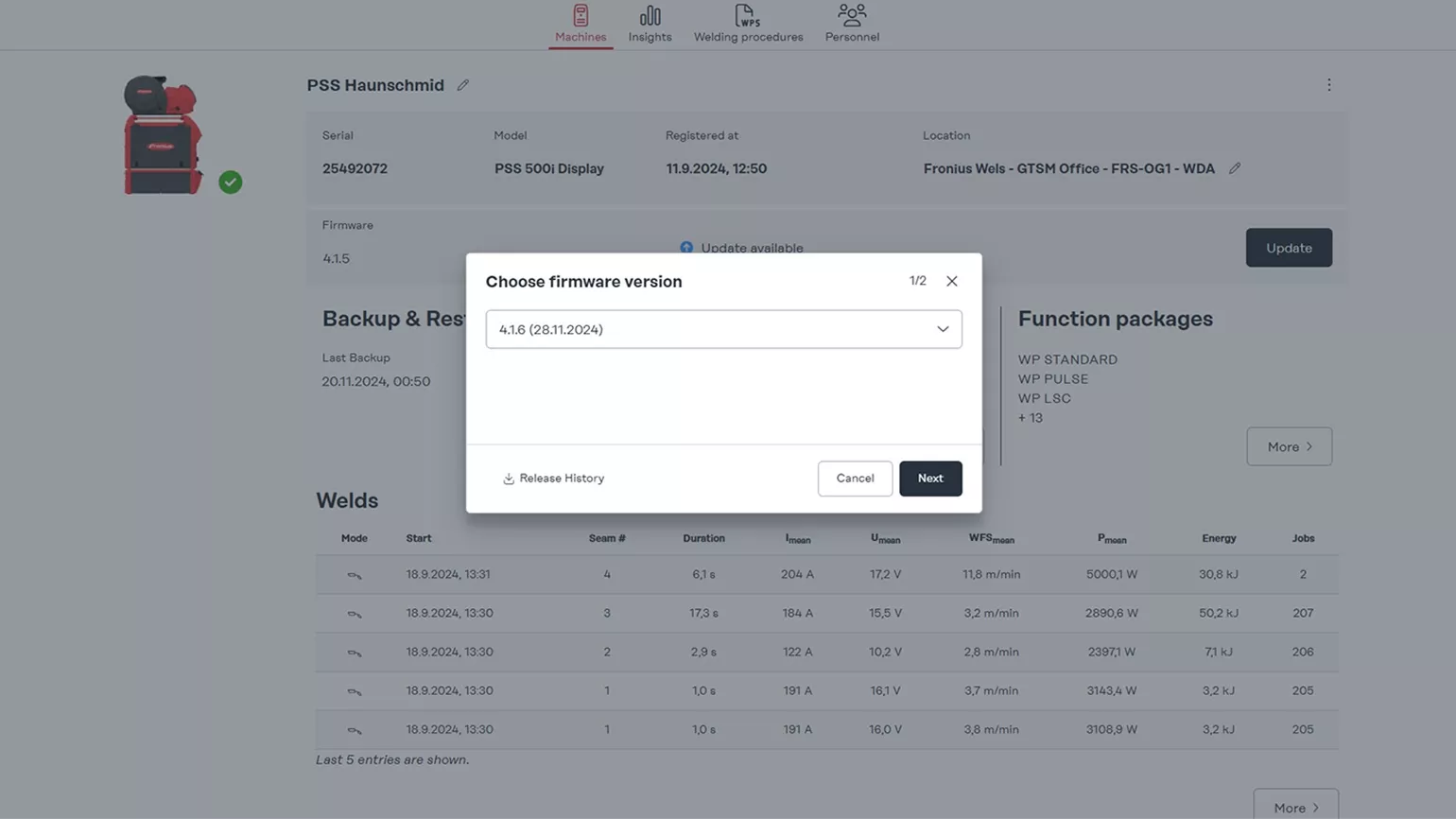

- Back-up und Wiederherstellung: Die einfache Rücksetzung der Konfiguration ermöglicht eine schnelle Fehlerbehebung und reduziert Stillstandszeiten effektiv.

- Wartung optimieren: Schweißsysteme zeigen aktuelle Vorgänge, Fehler und Warnungen in Echtzeit an, was einen reibungslosen Ablaufgewährleistet.

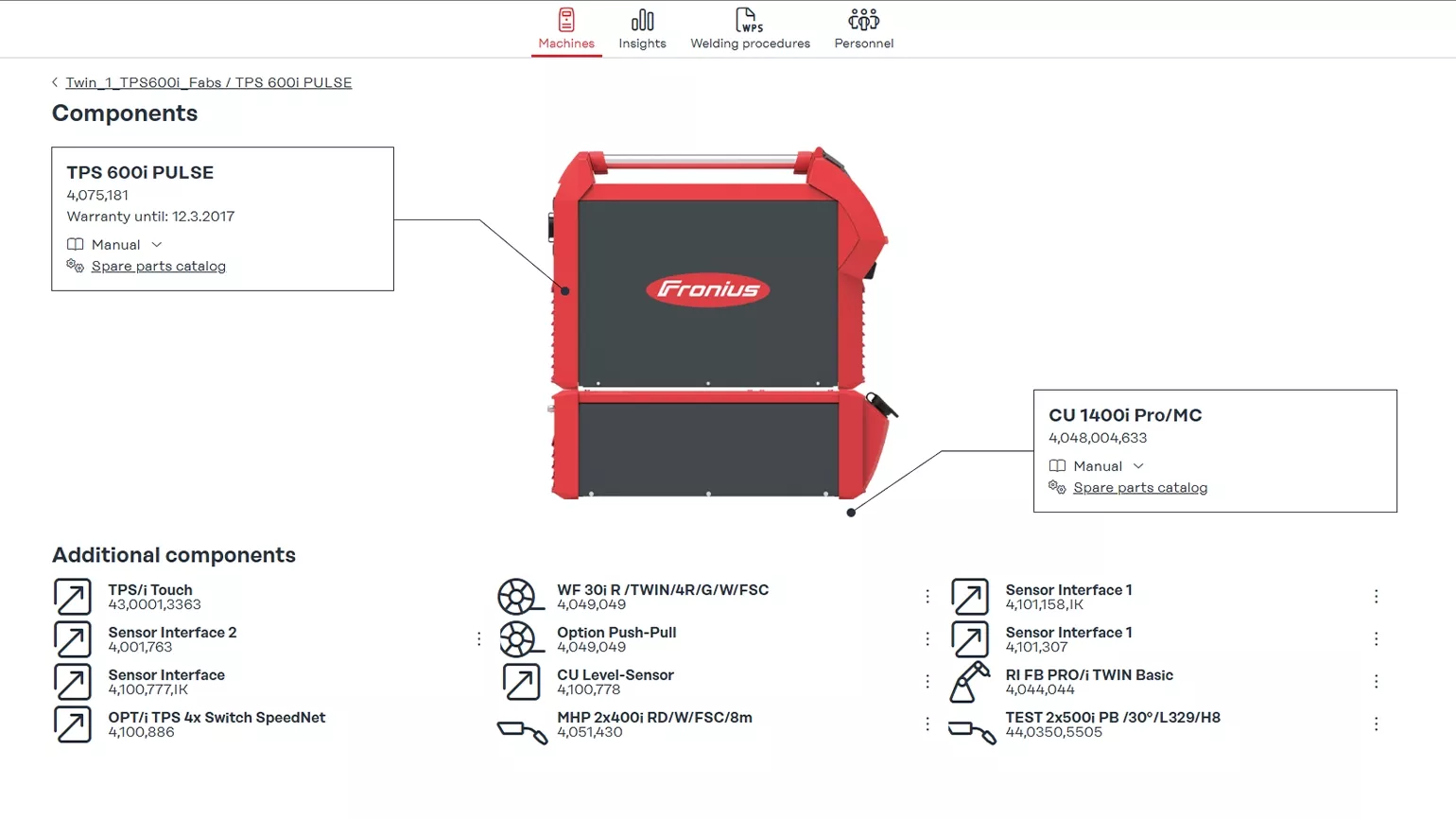

- Digitale Einblicke: Wichtige Informationen wie Bedienungsanleitungen, Ersatzteilkataloge und Wartungsdokumente sind in WeldCube Air auf Knopfdruck verfügbar.

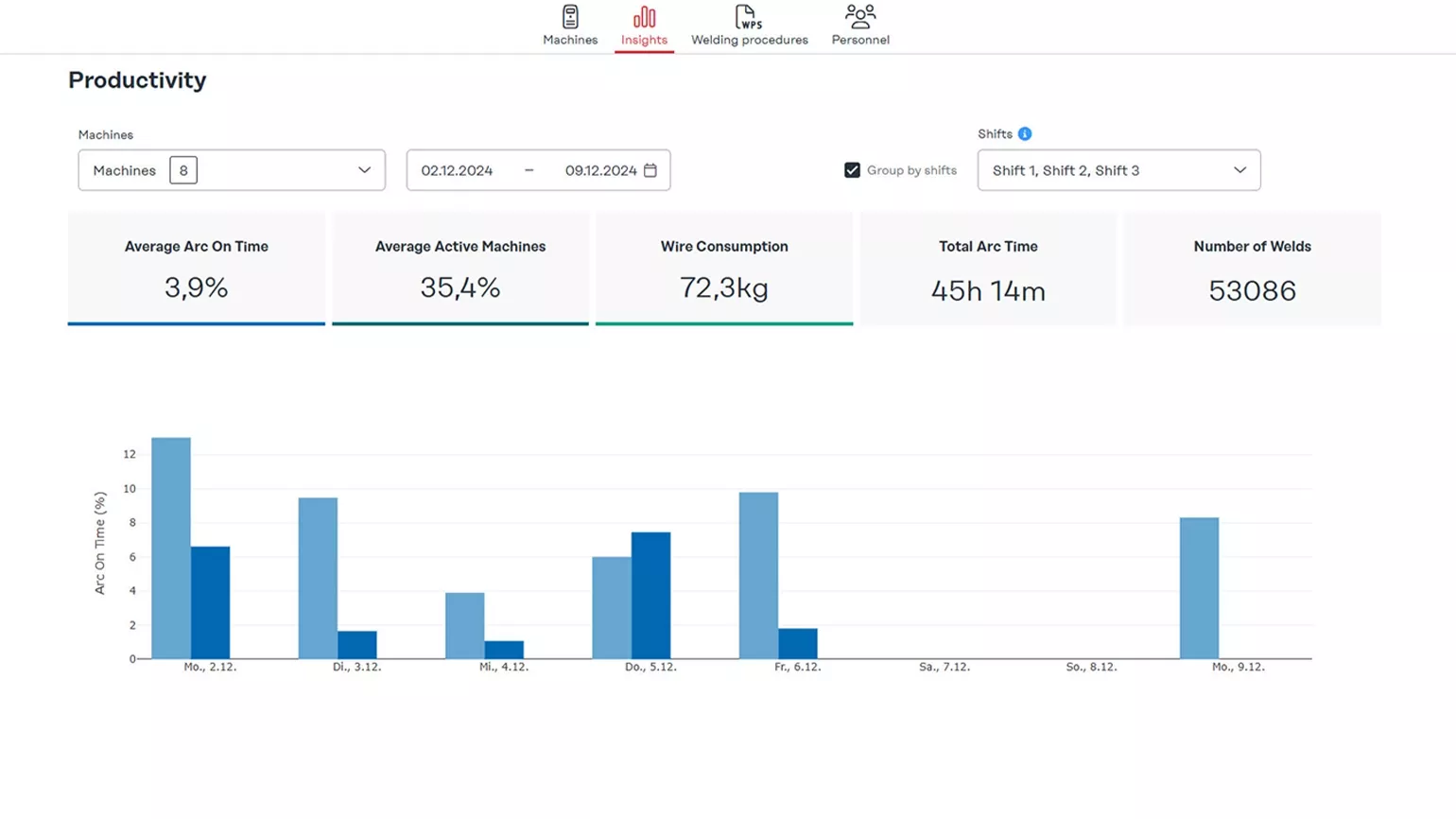

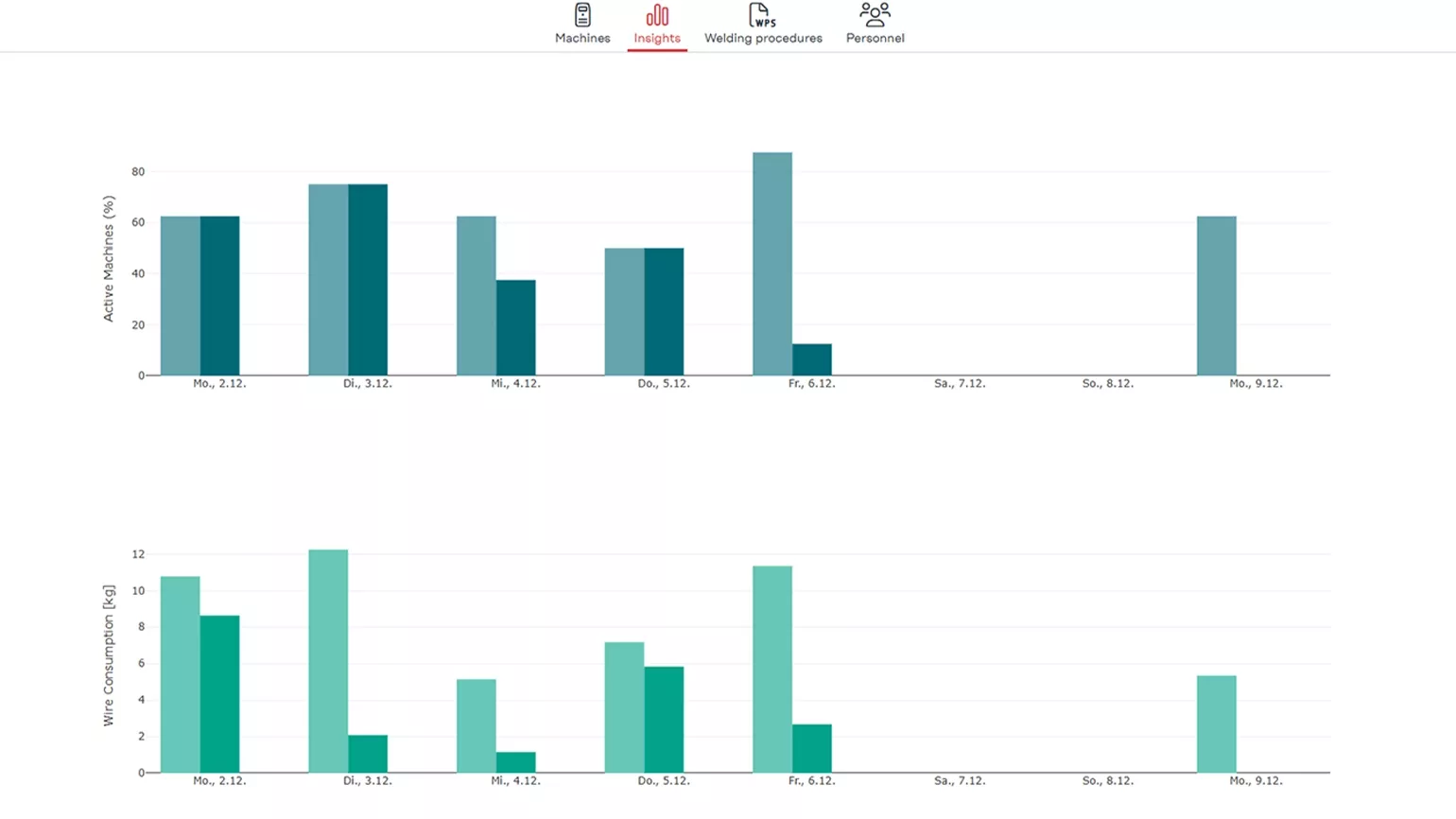

Produktivität im Blick

Mit datenbasierten Entscheidungen optimale Ergebnisse erzielen. Unsere Softwarelösung gewährtwert volle Einblicke in Ihre individuellen Optimierungspotenziale.

- Produktivität steigern: Verbessern Sie Ihre Produktionsabläufe durch die Analyse der Lichtbogen-Einschaltzeit.

- Optimieren Sie Ihren Verbrauch: Mit unserer Softwarelösung lassen sich Einsparpotenziale identifizieren und Kosten effektiv senken.

- Volle Transparenz: Ob absolut, relativ, als Durchschnitt oder nach Schweißsystem und Schicht – analysieren Sie Ihre Daten für Zeiträume von bis zu einem Monat.

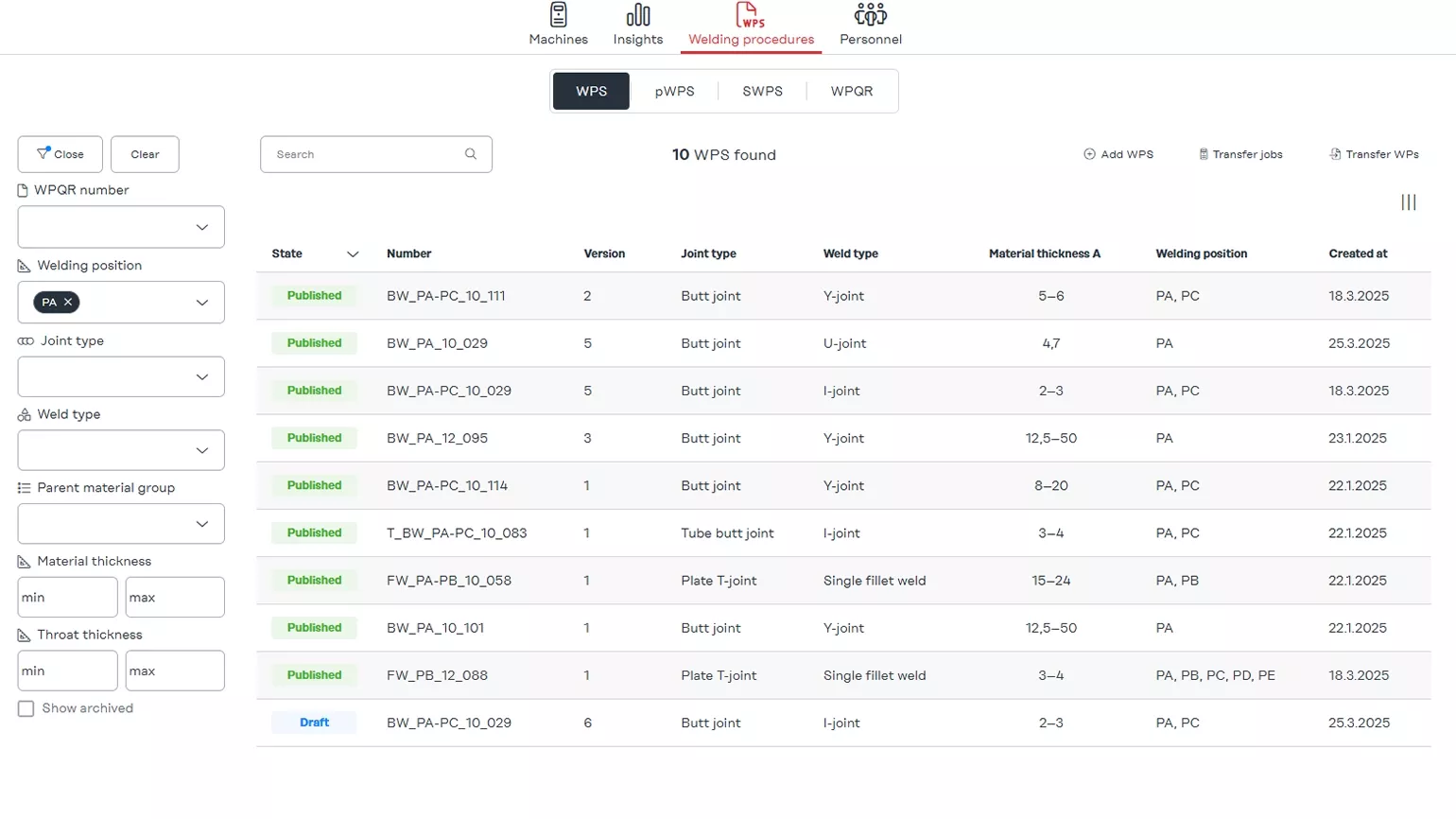

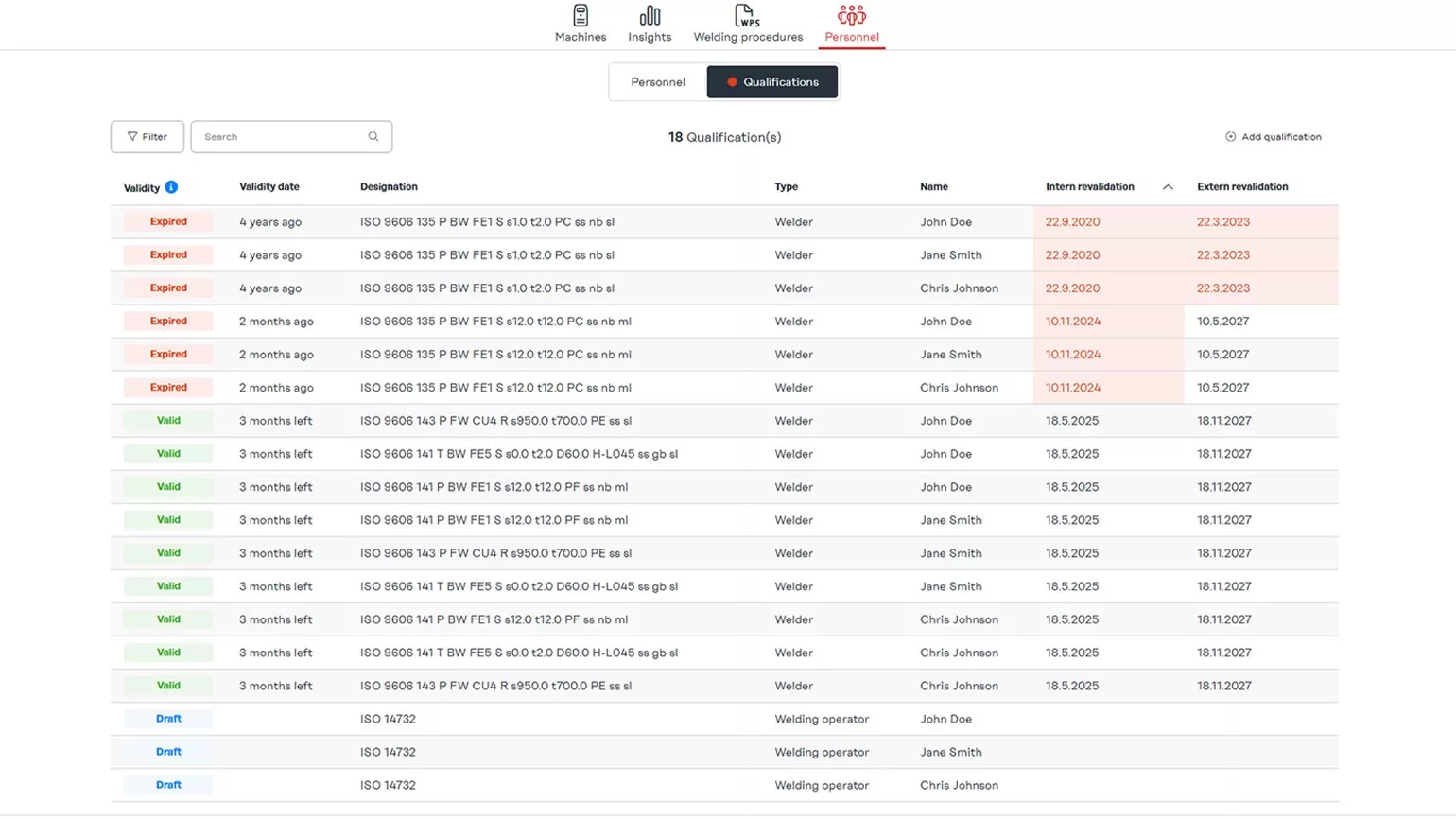

WPS & Qualifikationen

WeldCube Air unterstützt die Schweißaufsicht bei der normgerechten Verwaltung von Schweißanweisungen und -zertifikaten sowie deren Nachverfolgung und Validierung.

- Zentrale Übersicht: Einfache Erstellung und Verwaltung von Schweißanweisungen und -zertifikaten an einem Ort.

- Suchfunktion: Schnelles Auffinden der relevanten Schweißanweisungen und Abgleich mit autorisierten Schweißfachkräften.

- Erinnerungsfunktion: Automatische Benachrichtigung zur rechtzeitigen Revalidierung von Schweißzertifikaten.

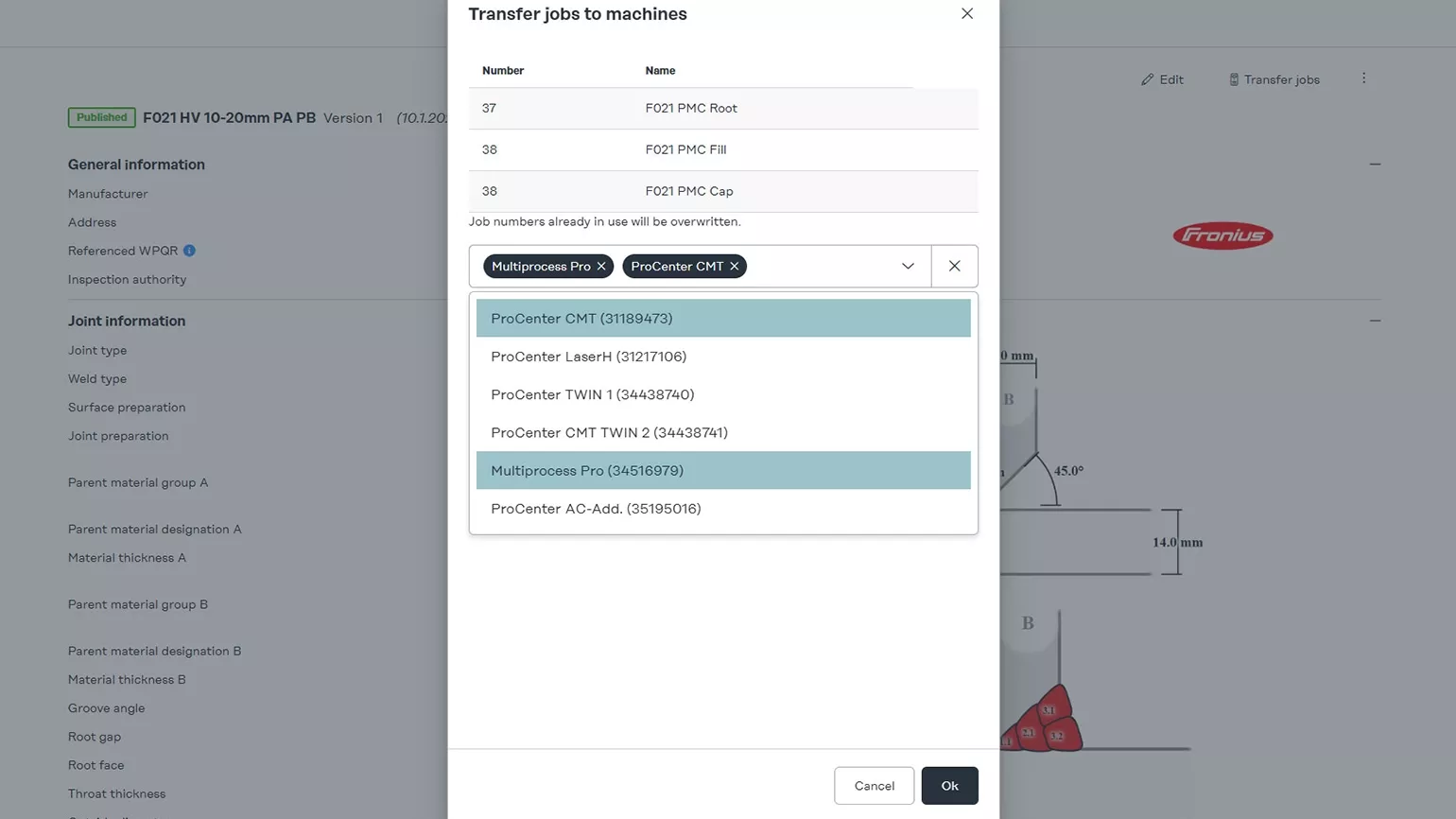

- Parametersets vorbereiten: Job mit Schweißanweisung verknüpfen und per Knopfdruck auf die gesamte Schweißflotte ausrollen.

Perfekt kompatibel mit TPS/i, iWave und Fortis

Wir denken voraus: WeldCube Air ist kompatibel mit TPS/i, iWave und Fortis. Somit sind Sie stets auf dem neuesten Stand und haben vollen Überblick über Ihre schweißtechnische Fertigung.

FAQs

- Der Drahtverbrauch in WeldCube Air wird auf Basis der verwendeten Kennlinie berechnet.

- Jede Kennlinie enthält Informationen zum Draht, wie Durchmesser und Dichte.

- Daraus wird von der Länge auf das verbrauchte Gewicht umgerechnet.

- Achtung: Es handelt sich immer nur um einen Richtwert! Fronius prüft nicht, welcher Draht tatsächlich im Schweißsystem eingelegt ist.

- ISO 15609, ISO 15613, ISO 15614-1

- ASME und AWS sind noch nicht verfügbar, werden aber nachgezogen.

- 9606-1 für Stahl, 9606-2 für Aluminium

- ISO 14732 (Welding Operator)

- Erstellen Sie einen passenden Job erstellen und fügen Sie ihn zur WPS (Welding Procedure Specification) hinzu (Datei hochladen oder direkt hinzufügen).

- Einmal eingerichtet, kann das WPS-Job-Set per Mausklick auf jedes mit Air verbundene Schweißsystem übertragen werden.

- Ja, das ist möglich (siehe Add Members).

- Sie können vorgefertigte Rechte vergeben, um zu steuern, wer was in WeldCube Air machen darf.

- Neue Benutzer können sich mit ihren bekannten Zugangsdaten (von myFronius) einloggen oder ein neues Fronius-Konto erstellen.

- Sie können sowohl Mitarbeiter Ihres Unternehmens als auch externe Personen hinzufügen.

- Die Basisversion (Schweißgerätemanagement und die Übersicht über die Produktivität) von WeldCube Air ist grundsätzlich kostenlos.

- Der Funktionsumfang kann jedoch durch Funktionspakete wie WPS & Qualification (kostenpflichtig) erweitert werden.

- Funktionspakete erweitern den frei verfügbaren Funktionsumfang von WeldCube Air (z.B. WPS & Qualifications).

- Die Funktion dieser Pakete kann kostenlos getestet werden.

- Funktionspakete können kostenlos getestet werden.

- Wenn Sie ein Funktionspaket vollständig nutzen möchten, können Sie direkt in WeldCube Air ein Angebot anfordern.